CIRCULAR CLARIFIERS

MODELS circular-clarifiers

OUTLINES OF THE SEDIMENTATION PROCESS

A good efficiency of the sedimentation process gives as a result a considerable reduction of BOD, COD, heavy metals, azote, phosphorus, etc. in the treated water. As the suspended substances in the waste water become larger, their sedimentation becomes easier.

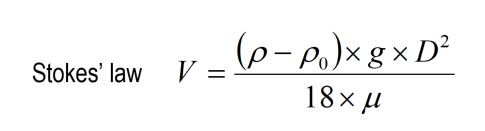

Stokes’ law emphasizes the importance of the floc size for the speed of sedimentation.

V = speed of sedimentation in m/s

ρ = density of solids in kg/m³

ρ0 = densità dell’acqua kg/m³

g = 9,81 m/s2

μ = viscosity of water in in Pa x s (at 15° C the viscosity of water is 1,06 x 10-3 Pa x s)

D = diametre of the particle in m.

A good way to obtain large flocs in the clarifier feeding is the installation of baffles using the kinetic energy of water to agglomerate the flocs to each other

In the secondary clarifiers, the type of scraping blades and the sizing of the central drain well are very important.

Actually, given the enormous volume of “sludge” compared to the feed flow rate (50%), we can hypothize that the sludge characteristics are just a little different from the ones of the clarified water (under static conditions the clarified water and the sludge stratify with a horizontal separation surface) and that, consequently, due to the slight bottom slope (∼ 4%), it flows naturally towards the central well. However, we should not forget that the particles which touch the bottom, and the ones which stratify, adhere and loose the properties of “fluid”: so they must be actively moved and “pushed” towards the drain well before the layer becomes too thick and, above all, before the anoxic condition causes a strong de-nitrification with the production of floating plates.

Therefore all of the sedimented sludge particles conveyed by the bottom scrapers to the central well from the tank periphery, must reach it quickly. This is achieved by giving a continuous profile with logarythmic shape to the blade; the relevant equation in polar coordinates is:

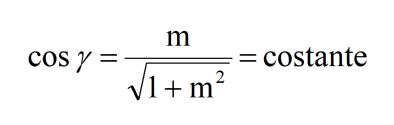

where r and α are the polar coordinates having the tank centre as a pole and ro is the radius of the drain well. Under these conditions, the scraper moves the sludge, makes it more “fluid” (by eliminating the adhesion) and conveys it by a perpendicular force to its surface (Pascal); this force has a radial centripetal component, not null and constant.

The angle γ is determined by: